How does a cutter suction dredger work?

Learn how a cutter suction dredger works.

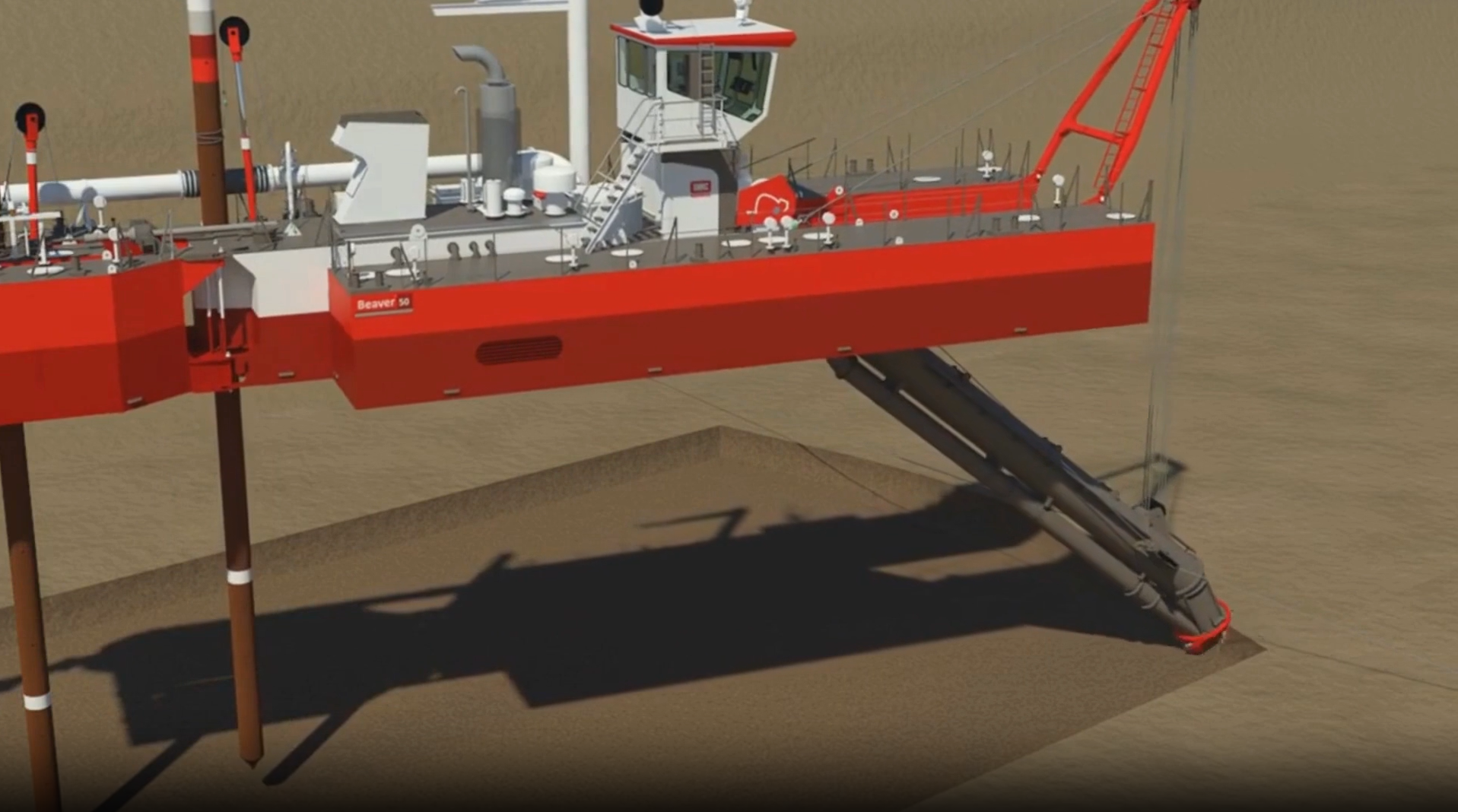

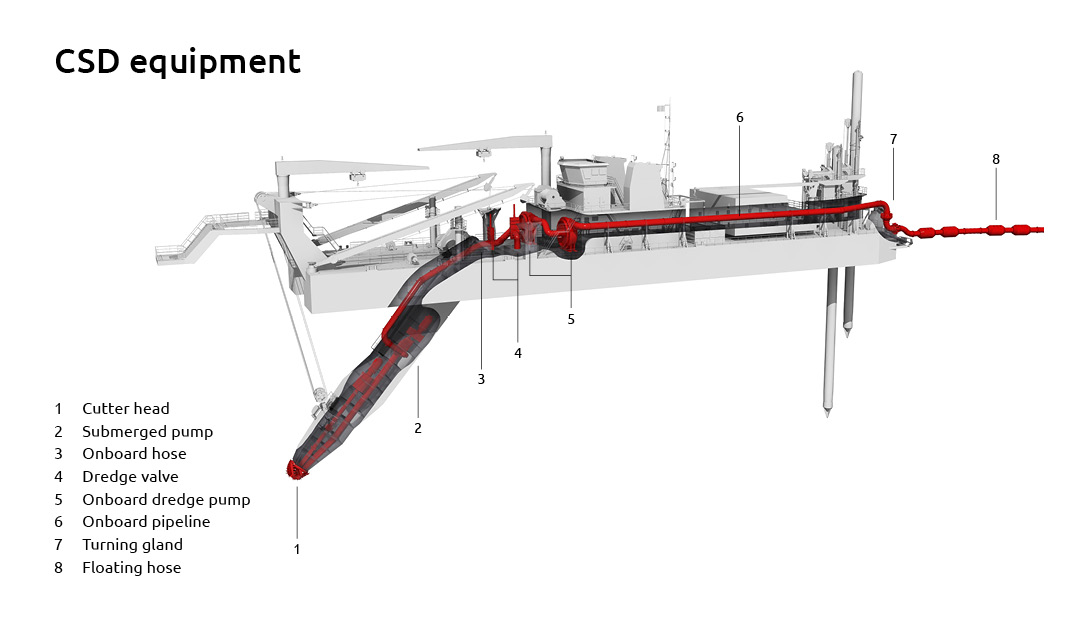

Cutter suction dredgers (CSDs) combine the two basic principles of dredging: excavation and suction. A rotating cutting tool dislodges the soil so that it can be drawn into a suction pipe. This type of dredger can handle all kinds of soil, from sand and gravel to heavily compacted and hard materials such as clay, soft rock and even thin layers of hard rock. Therefore, CSDs can be used for a wide range of dredging projects, including land reclamation, port construction and waterway maintenance, mining, reservoirs and hydropower lakes excavation and environmental dredging.

Whilst dredging, CSDs remain stationary by means of a spud that is lowered into the seabed. The dredger dredges by making a sideways swinging motion using anchors and winches. That way, very accurate dredging results can be achieved. The dredger moves forward by lowering the second spud – the so-called walking or auxiliary spud – for a short period, allowing the operator to reposition the working spud. Hence, CSDs are not designed to operate in swell conditions. The movements of the vessel may bend the spuds or damage the hinges of the ladder. Utilising central anchor systems (Christmas trees) instead of spuds can extend the workability in swell, but this affects the manoeuvrability and efficiency of the operation.

Main features of CSDs:

- combination of mechanical excavating and hydraulic dredging with centrifugal dredge pumps and a rotating cutterhead

- stationary dredger – large, custom-built CSDs can be self-propelled, but they do not sail whilst dredging

- accurate dredging system with good control on vertical and horizontal position

- suitable for almost any type of soil including soft rock and rock of moderate strength

- transport of dredged materials through pipelines

- dismountable and transportable over land

- allow for single-handed operations

- production of up to 6,000m3/hour.

Dredging cycle of a cutter suction dredger

The basics of a cutter suction dredger (CSD) are simple: it is a matter of loosening the soil, sucking it up, transporting it via pipelines and disposing it either at the disposal site or in a hopper barge. But in order for the dredger to dredge a certain area, different movements have to be made. This is where cuts, swings, strokes and steps come into play.

To explain the different movements of a CSD, we assume that the dredger is already in place. This means that the work spud sits in the soil, the vessel is positioned in the axis of the section to be dredged, the anchors are placed sufficiently outside the cut, and the ladder and the suction mouth are submerged.

Swinging

The actual cutting of the soil by a CSD takes place in an arc shape. The work spud acts as an anchor point around which the cutter is swung. This swinging motion is achieved by hailing the anchor wire on one front side winch and paying out the other anchor wire. Subsequently, the cutterhead is pulled in the other direction.

Stepping: moving forward

At the end of a full swing, the dredger has to move forward so that it can start the next cut. The way the dredger moves forward depends on its type of spud system.

Fixed spuds

In a spud system with fixed spuds, the work spud and the auxiliary spud are attached in a fixed position at the rear of the vessel. They can only be moved up and down, to lower them in the sea- or riverbed. When the dredger comes in a position where its axis forms a certain angle with the center line of the dredging section, the swinging movement is stopped and the auxiliary spud is lowered into the soil. Next, the work spud is hoisted. Then the suction dredger is swung around the auxiliary spud until it forms an angle that is equal in size to the previous angle. At this point the cutter is halted again, so that the work spud can be lowered and the auxiliary spud is hoisted again. Dredging is then continued according to the selected cut pattern. This system entails a relatively great amount of unproductive time, caused both by the actual stepping and by the fact that the suction dredger has to be swung twice over certain sections of the cut.

Spud carriage

A more efficient alternative is the spud system that includes a spud carriage. A spud carriage is a mechanism around the work spud that enables the dredger to move forward on the working spud over a certain length, without having to change the spuds. In general, the spud carriage is located in the centre line at the rear side of the dredger. Stepping forward is possible by riding out the carriage. When a dredger is equipped with a spud carriage there is a clear distinction between stepping and moving spuds. A stepping movement is made when the suction dredger is pushed forward with the spud carriage. When the spud carriage is fully extended and the dredger can no longer be pushed forward, the work spud is repositioned – similar to the stepping motion of the fixed spud system. The spud carriage goes back to its initial position and the riding out of the spud carriage starts again. The length over which the dredger can move forward on the spud carriage is called a stroke.

Shifting anchors

A CSD’s sideway sweeping motion is achieved with the aid of anchors. After the dredger has covered a certain distance, the anchors lay too far behind to effectively swing. That is when the anchors need to be shifted. CSDs with an anchor boom can shift the anchors easily themselves. In case a CSD is not equipped with an anchor boom, ancillary equipment is needed to pick up and shift the anchor, such as a workboat.

Want to know more?

Check out our complete overview of CSD's and their capabilities.