Onboard dredge lines

.JPG)

Onboard dredge lines in short

For optimum performance our onboard dredge lines are designed to ensure a whole system operates at minimal flow resistance. The construction of the dredge lines is of the ideal material in terms of cost/wear ratios and effective lifetime. We offer onboard pipelines and onboard hoses, which are further explained below.

Why choose our dredge lines?

Dredge lines of IHC Dredging are designed to withstand the most severe wear, because of the use of high-quality wear-resistant materials, modernisation with wear resistance and even wear of the whole dredge line system. The guaranteed product strength ensures a longer life-time, less maintenance and reduced downtime.

Dredge line type 1: onboard pipelines

We offer a wide range of pipe patterns and structures. Varying from simple straight pieces to complex three- and four-branched pipes. A complete pipeline assembly can contain: straight pipes, bend pipes, branch pipes and suction mouths.

Wear-resistance

We provide a range of wear resistant materials to deal with all kinds of wear.

| Product packages | Silt | Clay | Sand | Gravel | Rock* |

|---|---|---|---|---|---|

| Wearmet® - low wear | |||||

| MaxTop® - high wear, low weight | |||||

| Maxidur® 5 - extreme wear, high lifetime |

* for cutter suction dredgers

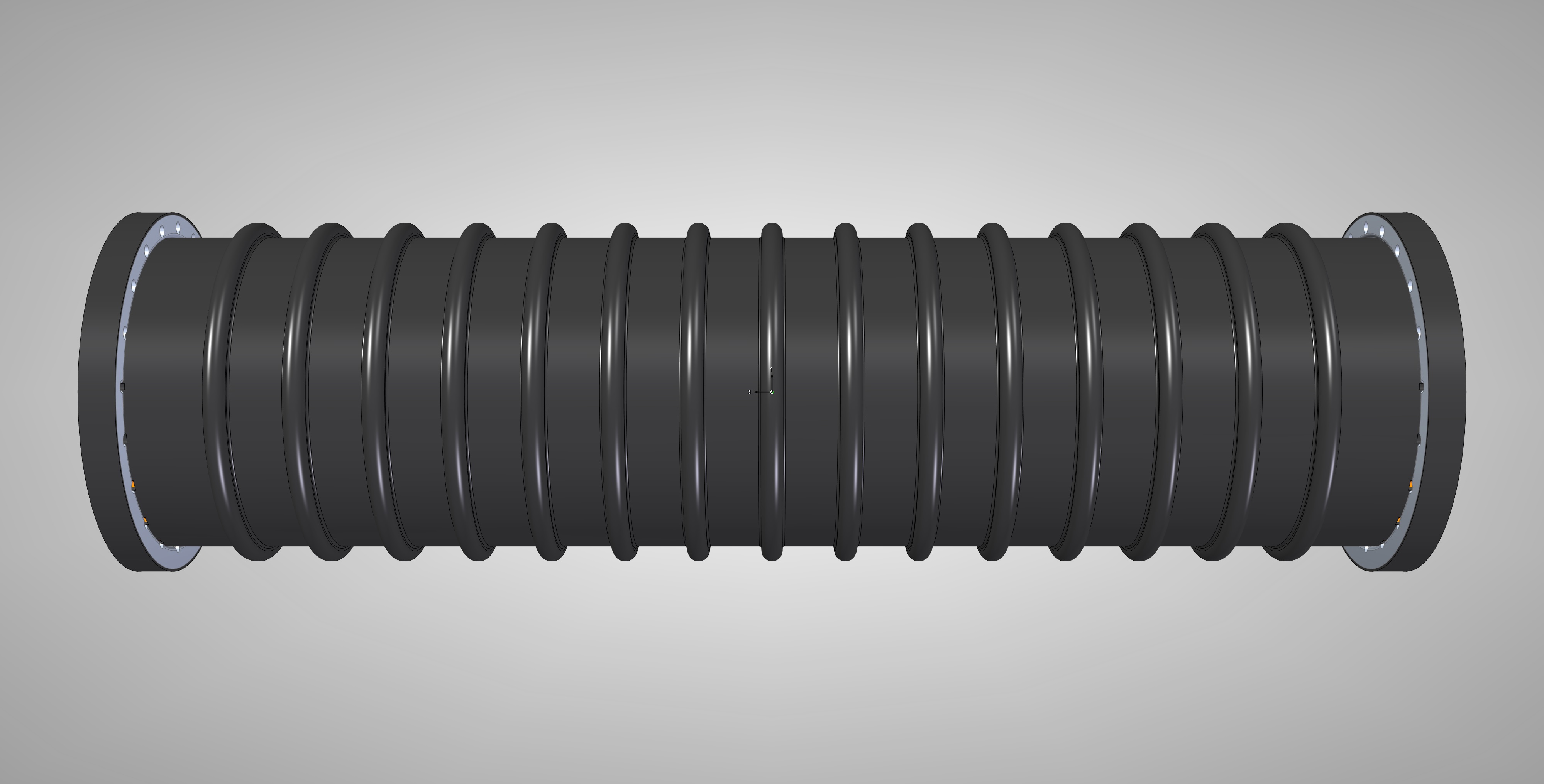

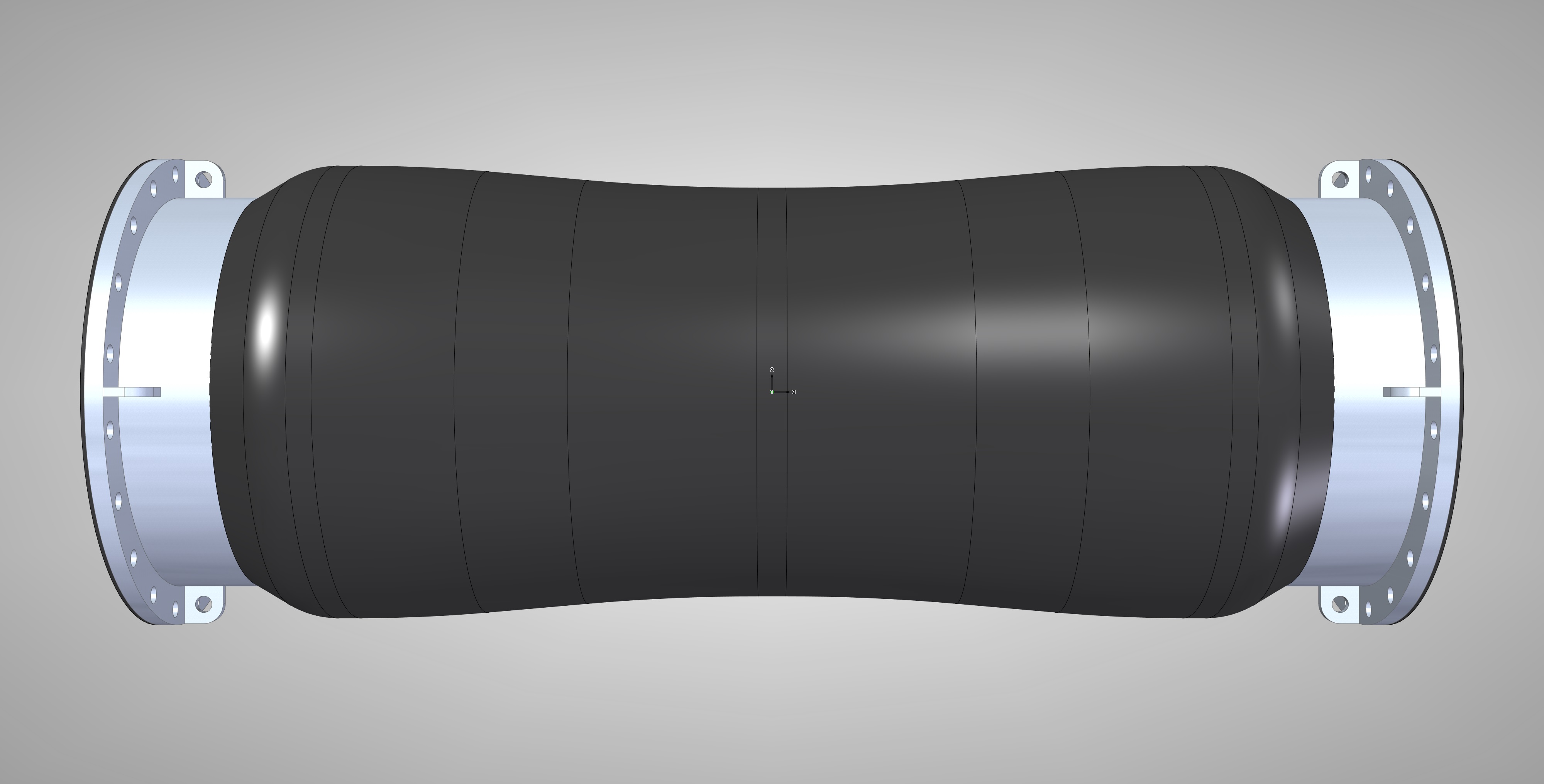

Dredge line type 2: Onboard hoses

The onboard hoses are flexibles for slurry transport and jet water applications. As standard we deliver our onboard hoses in a rubber wear layer suitable for low to medium wear environments. For more heavy wear environments, we offer you our armoured onboard hoses (except the jet water hoses). This onboard hose consists of a rubber wear liner combined with steel wear rings.

More information?

-

Erwin

BijvoetProduct Manager -

Bart

WarburgProduct Manager

Can we help you?

Please contact us to help you select the right onboard pipelines and hoses that suits your dredging project.